Kinco servo roller solution with feature of faster start and stop, high response, accurate positioning, compact integration, simple installation. It can greatly improve the sorting efficiency, improve the number of backage processed per unit time, the integrated structure of modules makes installation and debugging more convenient, and greatly shorten the time of equipment assembly.

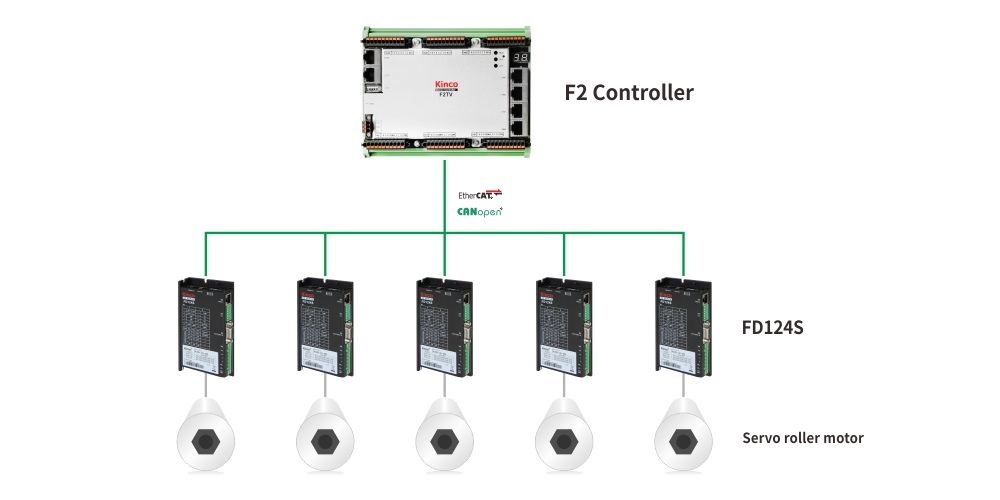

Kinco servo roller solution constitute of F2 controller, FD124S servo driver and roller motor.

1)No gear belt, simple installation, easy maintenance and low noise.

2)With 65536 resolution encoder, could accurate control the speed and position.

3)Designed for the roller sorting industry, with 400W rated power, 5Nm rated torque, and 700rpm rated speed, which can meet the requirements of most of the sorting.

4)Support Ethercat, Canopen and Modbus protocols, enable to connect with PLC such as Siemens, Beckoff and Omron, to meet various sorting communication needs.

5)Support cloud serve, could monitor product operation status and receive alarm prompt information through the mobile phone in real time.

1)Operating accurately and consistent acceleration: driven by servo electric roller, the upper side and lower side packages with different weight are more accurate, the acceleration is consistent.

2)High accuracy and rapid response: the car starts at millisecond level and starts at instantaneous completion, with faster response, higher efficiency and faster loop speed.

3)Smaller space and lower power consumption: integrated design, saving space, reducing the weight of the car, easy installation and maintenance, and reducing power consumption.

4)Communication capability: mature EtherCAT protocol, which can easily connect with controllers such as Beckoff, Omron and Keyence etc. The bus solution has stable and reliable operation experience of up to 1000 slave stations.

5)Real-time monitoring and predictive maintenance: real-time monitoring of product operation status, intelligent judgment of product health status, and effective prevention of fault problems.

© Kinco Electric (Shenzhen) Ltd.