As intelligent manufacturing progresses, the demand for higher equipment performance continues to rise. To address the complex application needs in production environments, Kinco has introduced the high-performance F2/G2/GL2 series HMIs.

Despite advancements in hardware performance, many enterprises still rely on traditional manual operations and maintenance (O&M) methods, such as on-site operation and manual inspections. This results in inefficiencies, slow response times, and challenges in maintaining production continuity and cost control.

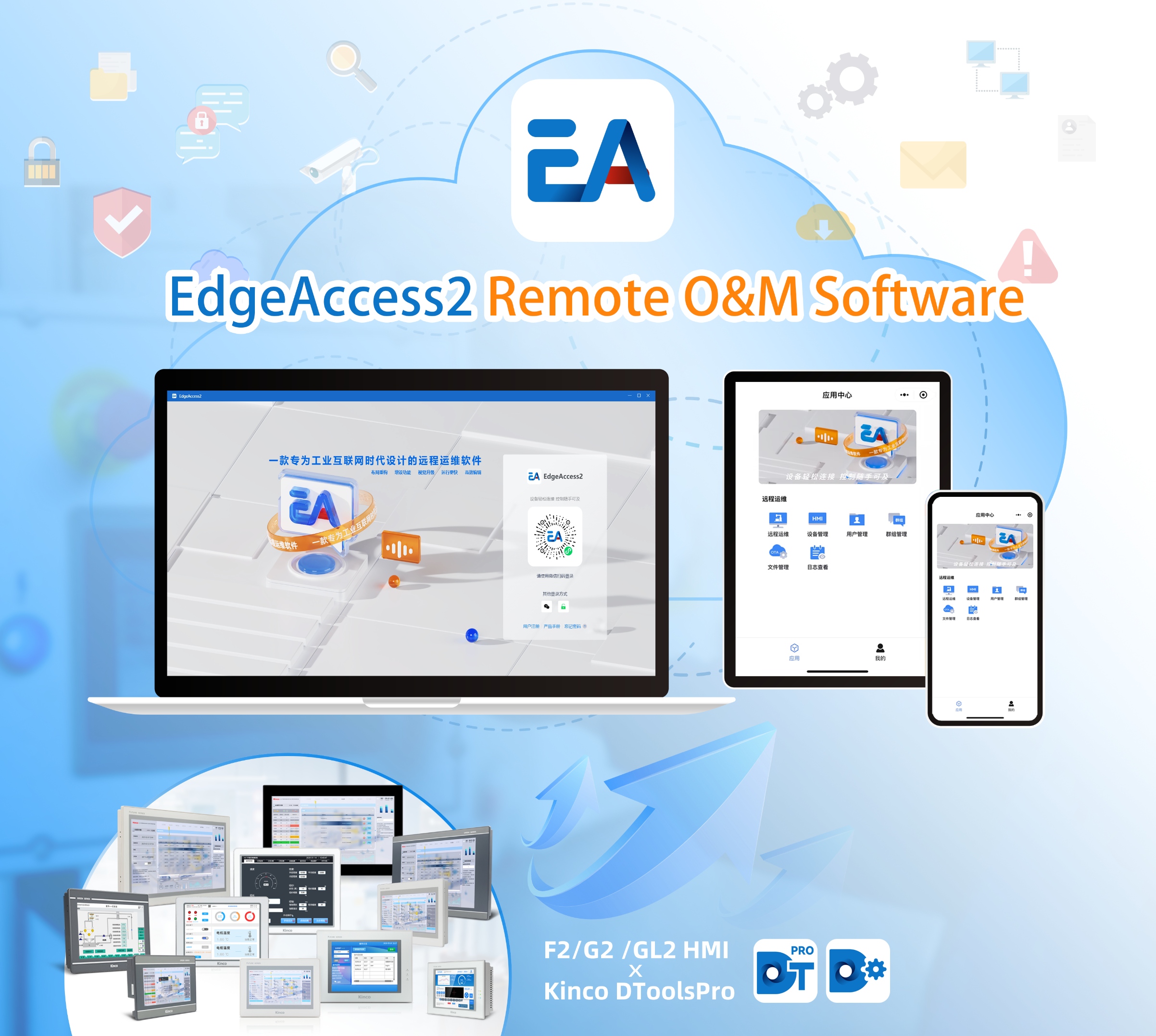

To meet the industry's urgent need for efficient remote O&M, Kinco has launched EdgeAccess2, remote O&M software designed for the F2/G2/GL2 series HMIs. This solution enhances O&M efficiency and transforms operational patterns.

As the ideal companion for Kinco DToolsPro, the latest configuration software, EdgeAccess2 leverages advanced point-to-point (P2P) technology to establish a secure, reliable, and convenient remote O&M solution. It offers efficient and safe data transmission, cross-platform compatibility, and an intuitive new user interface (UI).

P2P Technology for Superior Network Experience

P2P Technology for Superior Network ExperienceEdgeAccess2 utilizes advanced P2P technology to build a robust network architecture, significantly reducing the burden on intermediate servers, minimizing dependencies, and ensuring efficient and secure data transmission.

Cross-Platform Compatibility for Seamless Connectivity

Cross-Platform Compatibility for Seamless ConnectivityCompatible with Windows, Linux, macOS, iOS, and Android, the software supports both desktop applications and mobile terminals (including WeChat Mini Programs +H5), enabling O&M services anytime, anywhere.

Enhanced Security with Comprehensive Protection

Enhanced Security with Comprehensive Protection· End-to-end encryption ensures secure data transmission.

· Smart routing enables dynamic multi-path switching for improved connection stability.

· Private servers are available.

· Users retain full control over network keys and configurations, ensuring robust security.

High Performance with Ultra-Low Latency

High Performance with Ultra-Low LatencyModern network protocols enhance high-speed data transmission, reducing latency and jitter, ensuring smooth O&M operations.

Seamless integration with Kinco DToolsPro enables effortless remote uploading and downloading of HMI programs. User information can be distributed with a single click, doubling O&M efficiency.

Supports major PLC brands, including Siemens, Mitsubishi, Omron, Beckhoff, and Inovance, for online debugging and real-time synchronization.

· Built-in DTP View independent desktop software and VNC remote desktop software.

· The independent desktop function enables asynchronous collaborative control and debugging by multiple remote users.

· The VNC function supports synchronous control and real-time device monitoring without interfering with local operations.

Supports batch distribution of files, data reports, and images, simplifying O&M file management.

Background parameters can be monitored and adjusted in real time, ensuring stable equipment and system performance.

· Supports online updates without requiring downloads.

· Provides online English training documents with precise keyword search, helping users quickly familiarize themselves with the software.

Accurate user operation logs enable seamless tracking and auditing, reinforcing security management and compliance review.

For large venues such as buildings, enterprises, and factories, equipment is often distributed across various locations. Traditional management methods require frequent on-site visits for upgrades and troubleshooting, leading to inefficiencies.

EdgeAccess2 allows operators to remotely monitor and manage heating and cooling systems across multiple locations using computers or mobile devices. Real-time access to operational status, energy consumption, and fault warnings helps identify and resolve issues promptly, reducing risks and costs while enhancing operational efficiency.

① Improve employee work efficiency.

② Real-time equipment monitoring for enhanced stability.

③ Improved equipment informatization for intelligent management.

④ Reduced equipment failure risks and lower O&M costs.

As business scales expand, packaging product varieties increase. Traditional manual packaging is inefficient, prompting companies to adopt intelligent management solutions.

Solution

With EdgeAccess2, operators can monitor real-time operational status, key parameters, and packaging progress remotely. In case of abnormalities, the system issues alerts, allowing operators to adjust parameters, restart equipment, or dispatch technicians efficiently. This ensures accurate and uninterrupted packaging operations.

① Lower manual maintenance and operational costs.

② Enhanced product quality and rapid response to production changes.

③ Intelligent and centralized remote equipment management.

Copy the link to the browser: https://eaeur.m-iot.net/doc/

Note: EdgeAccess2 software is compatible with Kinco DToolsPro V1.7.7 and later. To ensure the best experience, please download and use the corresponding software version.

© Kinco Electric (Shenzhen) Ltd.