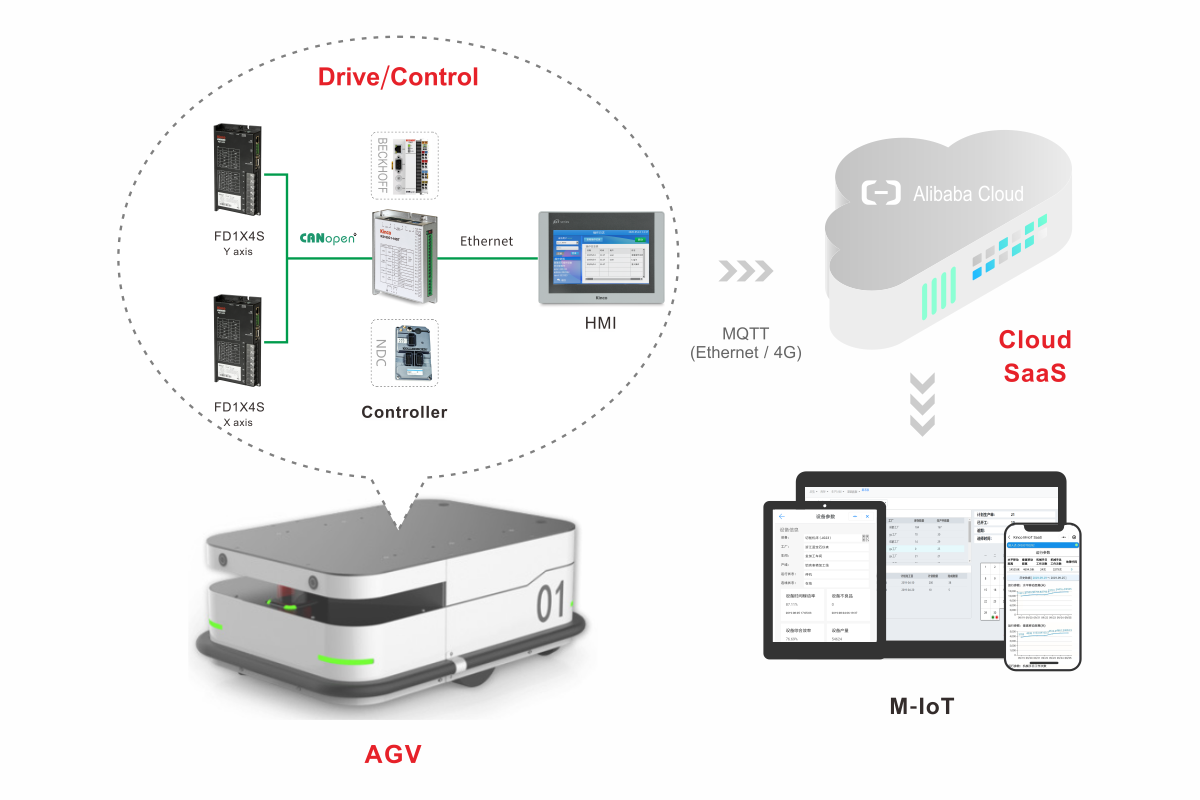

Kinco AGV automaiton and IoT control solution with Stable, Reliable, and Efficient feature. It could pass the AGV running parameter to the cloud via HMI, which realize monitaring the AGV running staus remotely, helping customer extend equipment service life, and lowing down operational management cost.

© Kinco Electric (Shenzhen) Ltd.