APPLICATION CASES

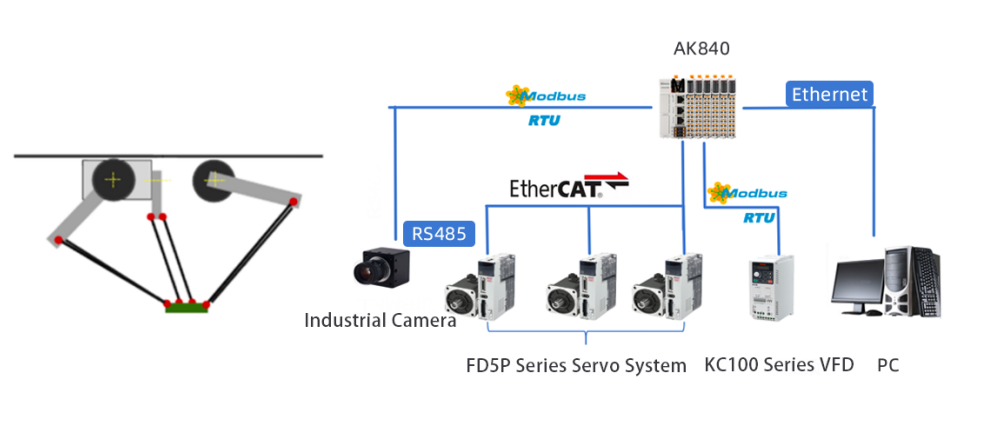

Parallel Manipulator Visual Material Sorting System

In actual automated production, in addition to the unique process realization of each industry, the material sorting link of the serial process automation realization is particularly critical: the required materials are sorted according to the process requirements in a specific surface, a specific order, and a particular distance of interval for the next process.

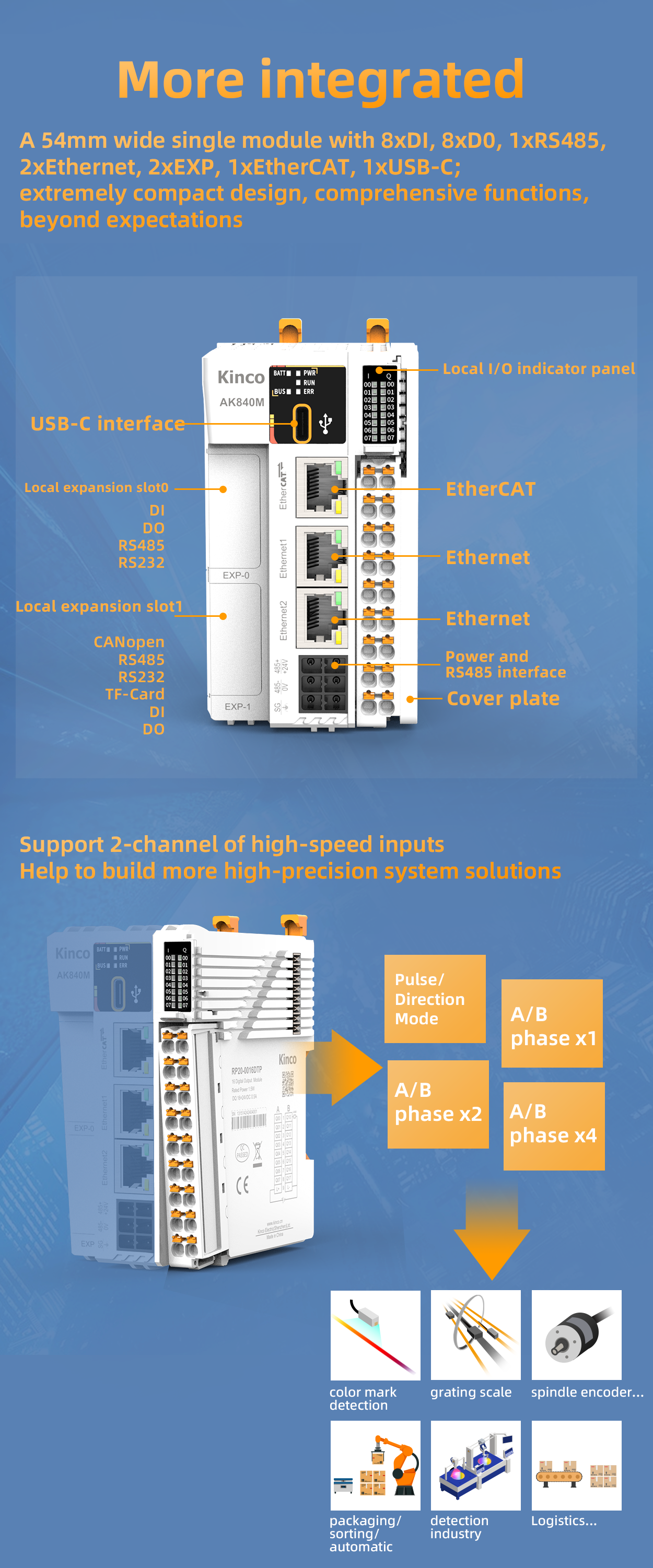

Kinco uses the AK840 EtherCAT-based controller with a visual system to complete the material sorting process of shaking materials → visual recognition → positioning absorption (grasping) → positioning placement → transmission, and successfully realizes the manual replacement of the production process. The material sorting efficiency can be increased by 16% compared with general workers, replacing high labor with low cost and achieving high efficiency, high intensity, and low work delay rate.

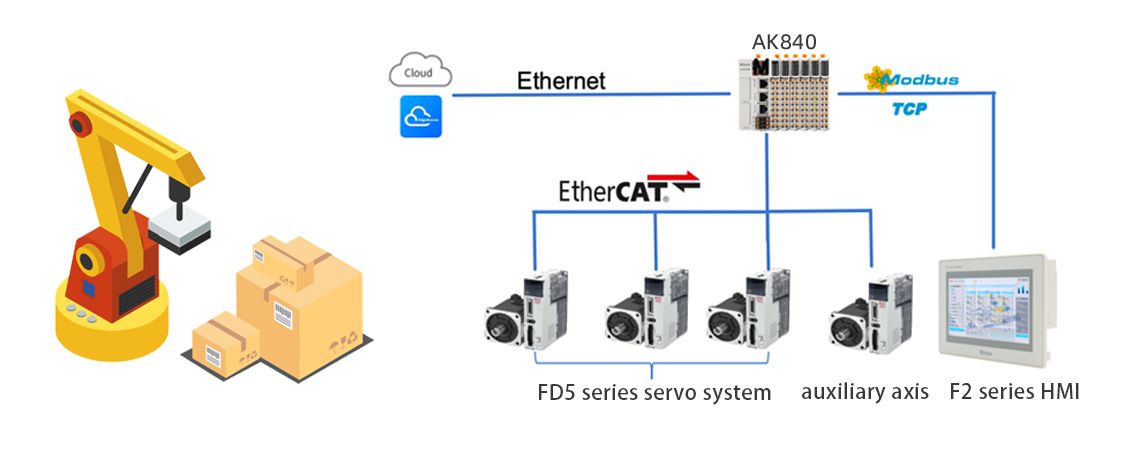

Logistics Industry Palletizer

The palletizer in this application is mainly composed of gantry bracket, lifting assembly, rotating assembly (double), clamp assembly, etc.

The plane coordinates are composed of horizontal and vertical directions to accurately determine the target position of the goods and implement the grabbing action, and then stack them according to the position of the target goods. Kinco uses AK840 medium-sized controller to complete the model establishment of the three-axis coder, and with F2 series high-end industry HMI, it realizes parameter setting, monitoring and alarm functions. Users only need to enter the corresponding height and number of stacking layers according to the different block products to be coded, which is simple to operate. The dual Ethernet design of AK840 not only takes into account the operability on site, but also takes into account the remote cloud data requirements.

© Kinco Electric (Shenzhen) Ltd.