As industrial automation continues to accelerate, heavy-duty Automated Guided Vehicles (AGVs) are becoming essential in industries such as port logistics, automotive manufacturing, energy storage, and heavy machinery. These AGVs often operate in complex environments while transporting loads exceeding 10 tons—demanding robust, efficient, and scalable motion control systems.

However, traditional 48V servo systems fall short in high-load scenarios due to high current requirements, thicker power cables, greater power loss, and limited scalability when managing multiple servo axes. To address these challenges, a new generation of higher-voltage, low-current solutions is urgently needed.

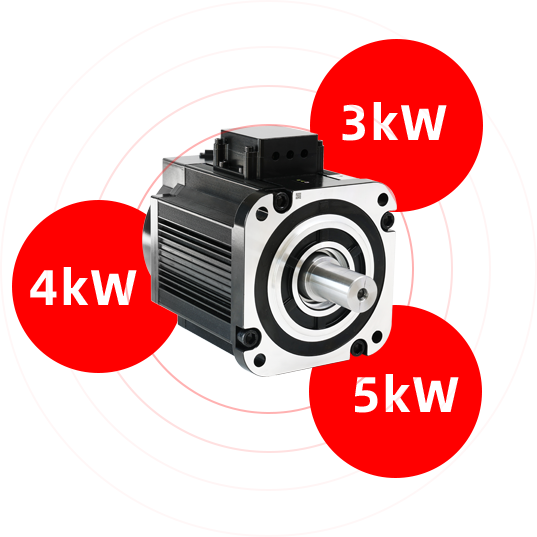

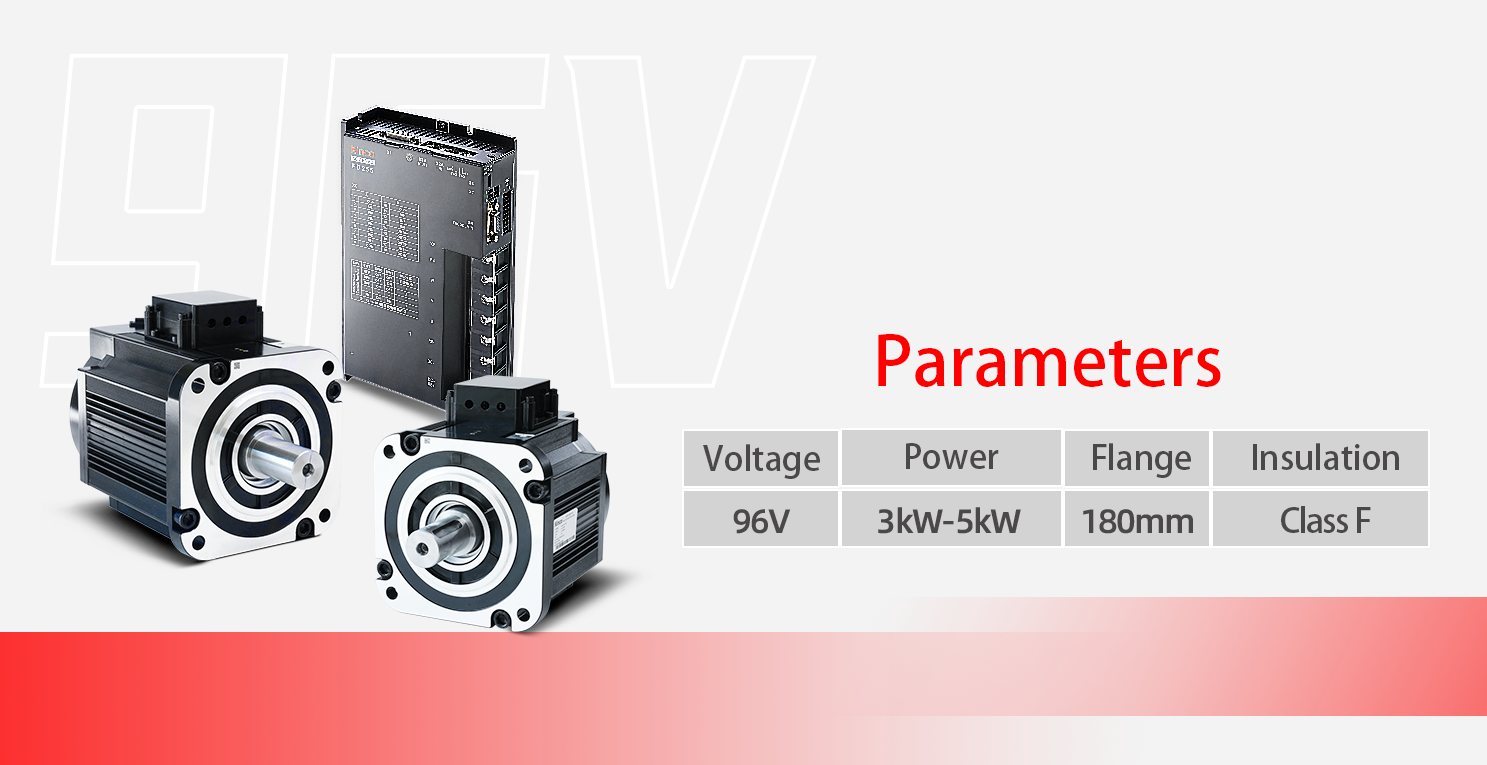

Building on the success of the proven 48V, 130-frame 1.5-3kW servo system, Kinco is proud to introduce its new 96V, 180-frame low-voltage servo motors and matching drives - available in 3kW, 4kW, and 5kW models. Designed specifically for AGVs handling loads over 10 tons, this new series delivers the power, efficiency, and reliability required for high-demand heavy-load applications.

The 96V system reduces current levels for the same power output, cutting down on resistive heat loss and improving overall efficiency. Less heat means longer motor lifespan, greater system stability, and more reliable 24/7 operation.

At the same current, the 96V servo motors can deliver significantly higher power, perfectly suited for heavy-duty AGVs. This translates to stronger propulsion, heavier payload capacity, and improved performance on complex terrains.

Ideal for AGV systems handling 10+ ton loads.

Enhanced Torque Density

High-performance magnets and magnetic circuit design for smoother low-speed operation.

>90% Efficiency

Up to 30% less heat generation, enabling continuous 24/7 operation.

Adaptive Power Output

Built-in load-sensing algorithms dynamically adjust output power to ensure stable operation.

Integrated Cable Design

All-in-one cable exit improves durability and protection while reducing wiring costs.

© Kinco Electric (Shenzhen) Ltd.