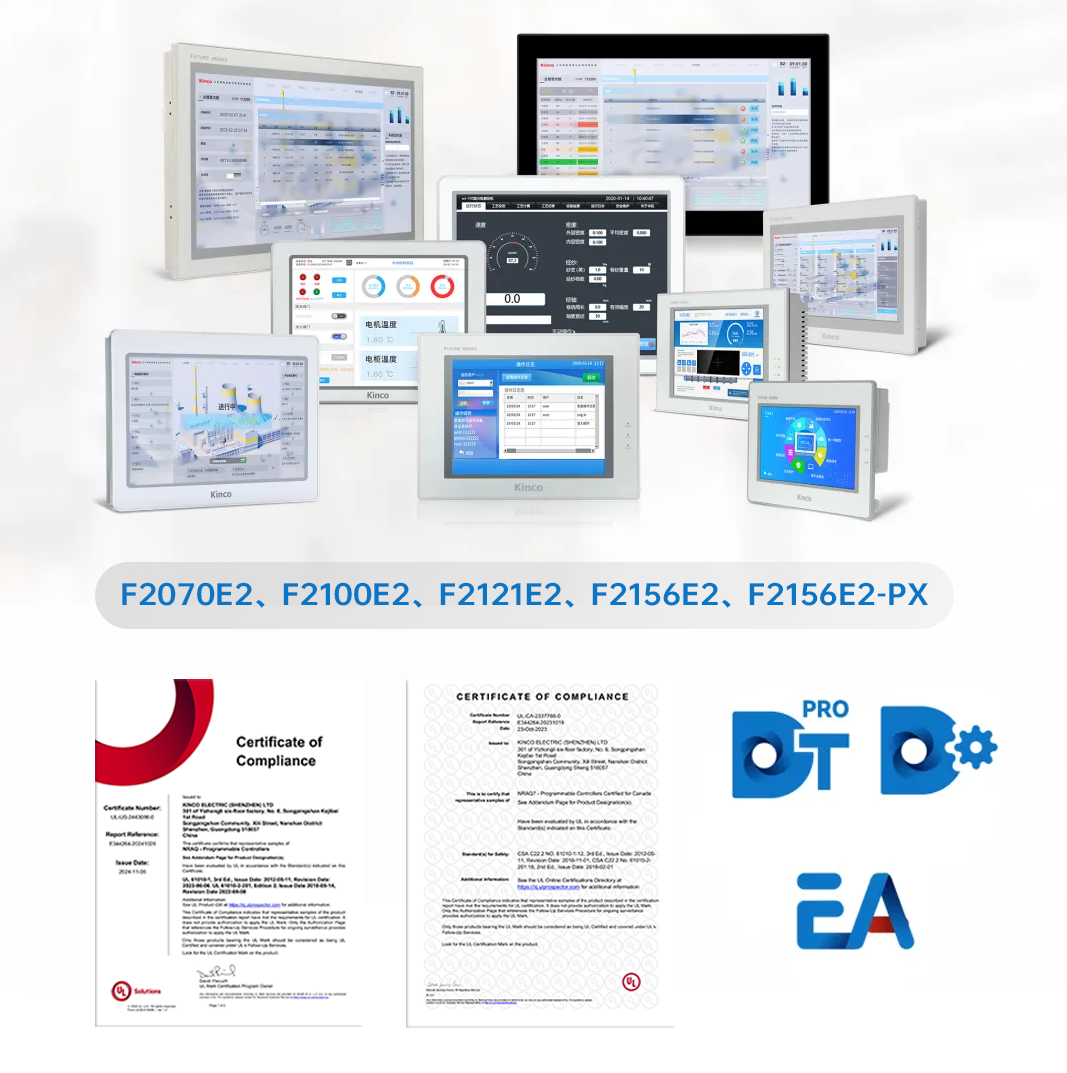

As intelligent manufacturing continues to evolve, higher demands are placed on the intelligence, efficiency, and safety of equipment. The Kinco FUTURE Series 2nd Generation HMI (F2070E2, F2100E2, F2121E2, F2156E2, F2156E2-PX) showcases its superior quality through robust capabilities, with the entire series officially certified by UL, supporting high-end manufacturing sectors such as lithium batteries, photovoltaics, 3C, and semiconductors in their global operations.

![]()

What is UL Certification?

UL Certification is an independent safety approval issued by Underwriters Laboratories, verifying that a product meets strict safety, performance, and regulatory standards.

Why is UL Certification Important?

UL Certification enhances product safety, builds consumer trust, facilitates international market entry, reduces legal risks, and strengthens brand reputation, making it essential for success in global industries.

Stable and Reliable - For Complex Industrial Environments

Kinco FUTURE Series 2nd Generation HMI

Comprehensive Model Range

Covering screen sizes from 7 to 15.6 inches, the F2 HMIs offer both capacitive and resistive touch screens. With high-definition, high-brightness, and full-view angle displays, users can easily select the right model for various industrial environments and application needs.

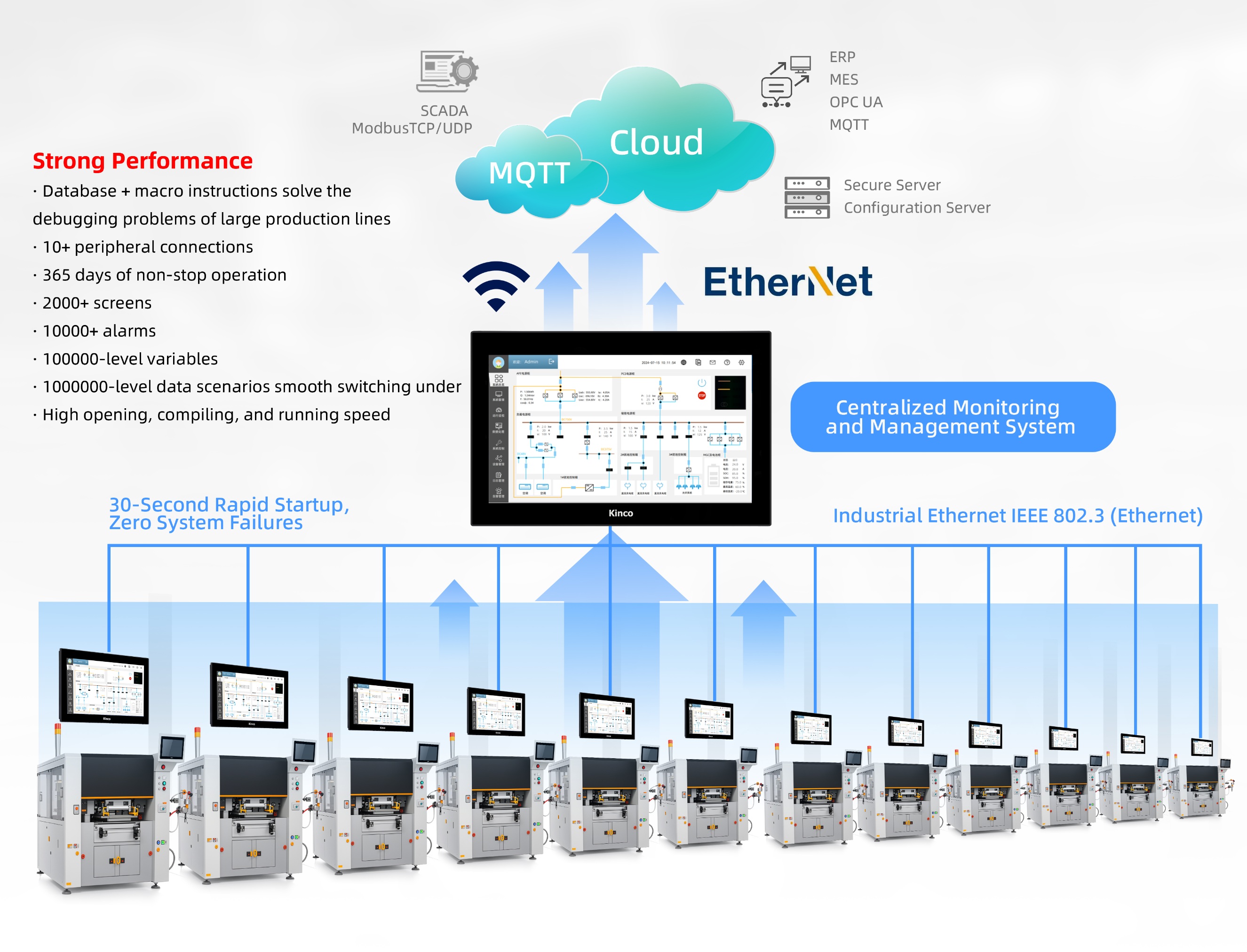

Powerful Performance

Equipped with a quad-core 1.8GHz CPU, 1GB RAM, and 8GB of storage, the FUTURE Series effortlessly manages over 2,000 screens, 20,000 alarms,and more than 1 million communication variables. It delivers smooth, uninterrupted 24/7 operation without lag, even under heavy-duty conditions. Paired with Kinco DToolsPro software, it can trace historical data for one year, ensuring seamless information management in smart factories.

High-Level Protection

Featuring original LCD high-definition displays with superior quality, the series is enhanced with conformal coating (three-proofing protection) and power isolation to protect PCBs. Built to industrial-grade standards, the FUTURE series offers strong anti-interference capability, waterproof, and dustproof protection, ensuring continuous, reliable operation even in extreme environments.

Rich and Flexible Interfaces

Equipped with dual Ethernet ports, dual serial ports, USB ports, and built-in driver-free RFID recognition. With strong peripheral expansion capabilities, the FUTURE Series seamlessly integrates with PLCs, MES systems, ERP platforms, and supports over 10 types of peripheral devices, providing maximum flexibility for various industrial automation needs.

Intelligent and Efficient - For New Energy Production

Kinco DToolsPro Configuration Software

Enhanced Development Efficiency

Powered by the Qt platform, Kinco DToolsPro significantly increases development efficiency for large and complex projects by up to 40%. It offers features like batch editing and preset templates, simplify project implementation and significantly reduce time and cost.

Screen Design Customization

With an integrated case library and UI design features, DToolsPro provides customers with a wide range of design references and fully personalized customization options.

Complete PLC Tag Communication

Kinco DToolsPro supports one of the most comprehensive PLC tag communication protocols in the industry, ensuring seamless integration with virtually all major PLC brands on the market.

Cross-Platform Compatibility

Fully supporting a variety of industrial automation protocols, DToolsPro is compatible with SQL, PostgreSQL, and other types of databases, enabling easy and efficient third-party database connectivity for smart factory ecosystems.

Real-Time Visual Monitoring

Allows users to create customized data dashboards with real-time updates, dynamic charts, and trend graphs, providing intuitive visualization of key production metrics for better operational insight.

Robust Security and Management

Built-in multi-level user permission management, automatic operation log archiving, and 365-day behavioral traceability ensure secure operations, user accountability, and enhanced data management reliability.

Collaborative Operation

Through an independent desktop architecture, DToolsPro enables multi-user and multi-station collaborative operations, with mutual-locking permission settings that guarantee data security while ensuring efficient system debugging and maintenance.

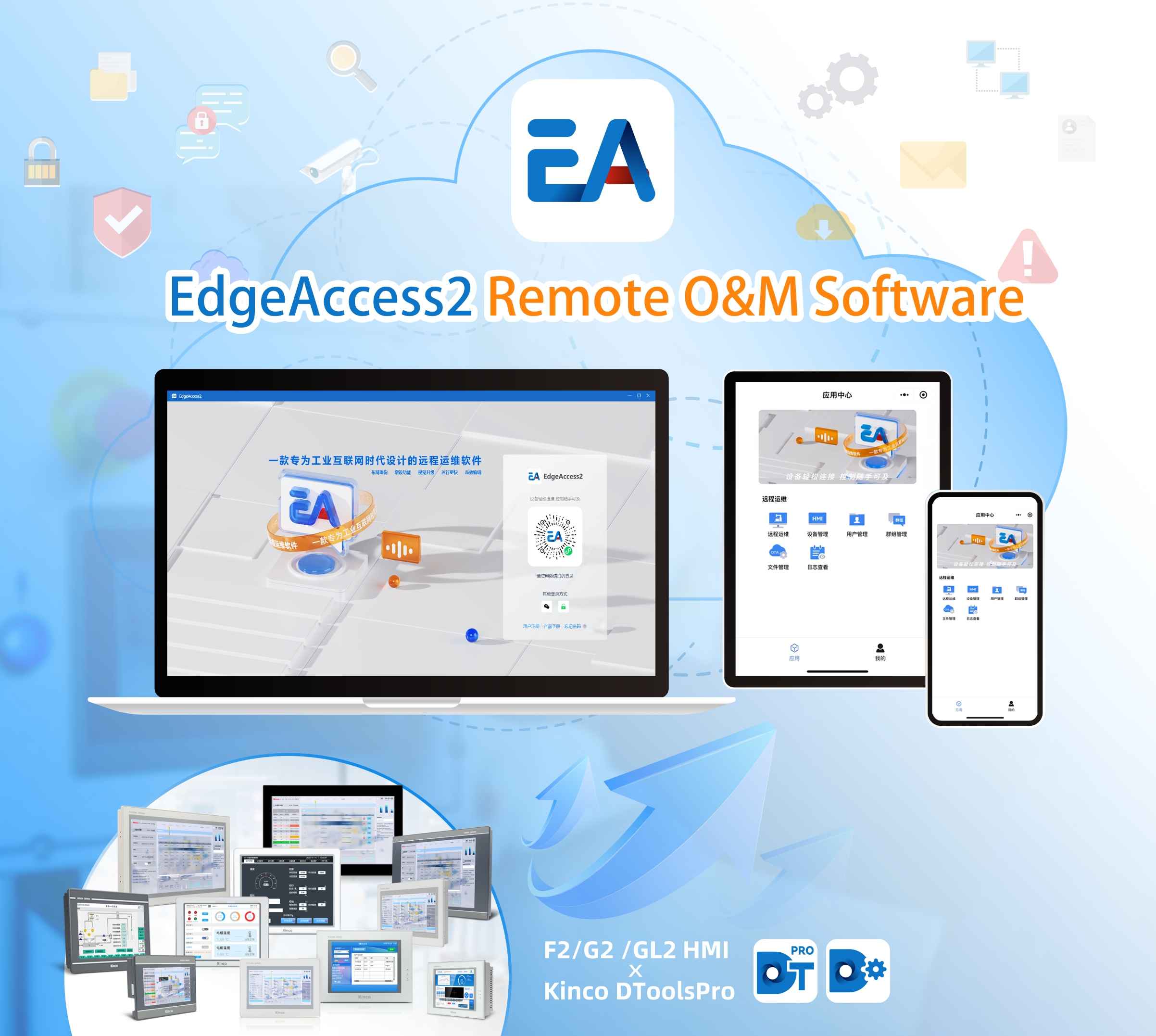

Remote Maintenance and Operation

Integrated with the latest EdgeAccess2 software, DToolsPro supports remote program updates, file management, real-time data monitoring, and pass-through, dramatically reducing maintenance costs associated with equipment accessibility limitations.

EdgeAccess2 Remote Operation and Management Software

① P2P Technology for Ultimate Network Performance

EdgeAccess2 utilizes advanced Peer-to-Peer (P2P) technology, dramatically reduces the load on intermediate servers, minimizes reliance on third-party networks, and ensures efficient and secure data transmission for industrial applications.

② Cross-Platform Compatibility, Seamless Connectivity

EdgeAccess2 fully supports Windows, Linux, iOS, and Android systems. Both desktop applications and mobile platforms (WeChat applet and H5) are covered, enabling users to enjoy seamless remote operation and maintenance services anytime, anywhere.

③ Security First, Comprehensive Protection

With end-to-end encryption technology, EdgeAccess2 guarantees secure and worry-free data transmission. Smart routing with multi-path dynamic switching improves connection stability. All servers, both domestic and international, are privately owned, and network keys and configurations are entirely controlled by users, creating an unbreakable security defense.

④ High Performance and Low Latency

By adopting modern networking protocols, EdgeAccess2 achieves high-speed data transfer, minimizing latency and jitter.

High-End Manufacturing Industry

In the high-end manufacturing sector, complex and large-scale production line equipment demands high efficiency, exceptional stability, and broad device compatibility. Due to the large size of the equipment and the need for extensive peripheral expansion — along with the requirement for continuous, non-stop operation — the FUTURE Series 2nd Generation HMI ensures long-term operational efficiency and stability through its powerful hardware configuration. This robust performance makes it an ideal choice for the demanding environments of advanced manufacturing industries.

Lithium Battery Pack Module Production Line

In lithium battery pack module production lines, the equipment layout is extensive, and the manufacturing processes are highly complex. Seamless collaboration across multiple workstations is critical. By leveraging the efficient development capabilities and custom library functions of Kinco DToolsPro, manufacturers can achieve rapid deployment and precise control. This significantly enhances production line collaboration efficiency, ensures smooth integration of production processes, and reduces overall maintenance costs.

Download Link

Kinco DTP HMI Catalog | Kinco DToolsPro Configuration Software | EdgeAccess2 Remote O&M

© Kinco Electric (Shenzhen) Ltd.